IQF stands for Individually Quick Frozen freezers. IQF means that every piece of food is frozen separately from others. This science is generally used in the culinary arts. The freezer that uses the technology of IQF (Individually Quick Frozen) is the IQF Freezer. Vacker KSA has been providing solutions to deal with along with facilitating on issues pertaining to cooking, all over the nation. We have been supplying IQF Freezers to the major cities in KSA and those major cities include Riyadh, Al Khobar, Dammam, Jeddah, etc.

If you have noticed then IQF foods are distinctly and separately frozen. The pieces of food do not freeze together turning into a pile or a lump with a thick layer of frost over the food. Rather each piece of food will be frozen separately. As a perfect example, a bag of peas can be taken. Next time you visit a departmental store for buying a fresh packet of peas then you must have a look at them minutely. You will notice that each piece of the pea is frozen and look alike. Many fruits, vegetables and meat are frozen using IQF freezers. Some of the examples are: corn, green beans, peas, seafood like scallops and shrimp, vegetables like green beans, peas and corn and meat like chicken breasts and much more.

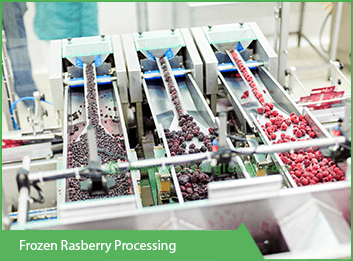

In IQF freezers a conveyor belt is fitted to a blast freezer that is supposed to freeze the item in a short proportion of time. The food items are individually sent in the conveyor belt into the blast-freezer that freezes the item very quickly. If you have noticed that the frozen foods are nonsticky and separate from each other, this is because the food items are sent separately in the freezer and stay separated after being frozen too.

The IQF uses cryogenic carbon dioxide gas or liquid nitrogen gas. With the use of this gas, the moisture, freshness and the shape of frozen foods are locked. Vacker KSA provides the users a very trusted and reliable IQF freezer to preserve the food with its freshness and moisture. The cryogenic IQF freezers from Vacker KSA is designed hygienically that discards the slowdown, bottlenecks and loss of product that are associated with the outdated freezers. The IQF freezers provided our company has efficient and hygienic freezing method.

Individually quick freezing with the usage of cryogenic CO2 gas or sometimes liquid nitrogen locks the moisture. Apart from locking the moisture, it also helps in maintaining the shape and overall freshness of the small food items that are stored in the freezers. As primary methods of individually quick freezing of foods, the flighted freezer has been in use since the last couple of decades. This orthodox method is however being replaced by modern and advanced methods of IQF. As a part of the culinary art, Vacker KSA has replaced the old and orthodox with newer and more efficient IQF freezers that are designed for hygiene and can reduce the chances of loss of products because of the outdated IQF freezers.

IQF Freezers are ideal for the following foods

- Protein rich food: Sliced pieces of meat that can be glazed or marinated, meatballs, fishes, shrimps, and other sea foods.

- Prepared foods: Pizza dough and toppings, dumplings and ready to bake items.

- Fruits and vegetables: a variety of fresh fruits and vegetables are kept in the IQF Freezers.

Vacker KSA is on the front line of providing IQF technology based freezers to all over the Kingdom and can fit solutions so that our customers find specific requirements.

We use different techniques in presenting a variety of IQF freezers so that you can keep your separate IQF products separately as they freeze. Majority of our products are highly efficient, hygienically designed that provide significant cost savings against all the flighted freezers.

For thick food or any other food that may require relatively longer freezing time, Vacker KSA has products in offer. For such foods, primarily immersion in cryo nitrogen is done and afterwards nitrogen gas is used.

Some of the IQF freezers that Vacker KSA supplies come with supplementary features such as the pulsators, bed vibrators and wave plates that help in separating the stored products in such a manner that results in maintaining freshness of IQF vegetables, with the shape, color and texture of the IQF stored products intact.