For many Cold Chain Management applications, there are critical constraints namely pressure, temperature, humidity, etc. that are needed to be monitored as well as recorded in actual time with alert systems in order to produce alerts when such constraints exceed the levels set. In general, it is termed as a Real Time Temperature Monitoring System. Of all the parameters, temperature is referred to as the most regular parameter that needs to be monitored and thus in general termed as Remote Temperature Monitoring. Vacker Saudi Arabia or KSA facilitates remote temperature monitoring in areas such as Riyadh, Al Khobar, Dammam, Jeddah, etc.

Real time monitoring system’s applications:

Some of the main applications that need real time monitoring system are as under:

- Monitoring of temperature in refrigerators that are used for storing medicines, etc.

- Monitoring of temperature and humidity of warehouses that store products (fruits, vegetables, medicines, vaccines, etc.) which are highly responsive to temperature fluctuation.

- Monitoring of temperature and humidity of cold rooms, cold storages, walk-in freezers, etc. that are used for storing medicines and vaccines, and other frozen foods.

- Monitoring of temperature for industrial freezers.

- Monitoring of humidity, temperature and condition of the engine for vehicles and reefers that are used while transporting goods that are sensitive to temperature.

- Monitoring of temperature and other parameters such as humidity, water leakage in server rooms and data centers. In such areas, monitoring of temperature is considered very critical because of the heat-generating nature of the server panels.

- Monitoring of temperature, pressure and humidity in hospitals especially in ward rooms, Intensive care units, Cardio care units, operation theaters etc.

- Monitoring of temperature, pressure and humidity at manufacturing settings especially inside clean rooms.

- Monitoring of temperature of kilns, furnaces, industrial equipment, autoclaves processing machines and many other such equipment.

- Monitoring of temperature in course of concrete curing.

Real time monitoring system’s operating principle:

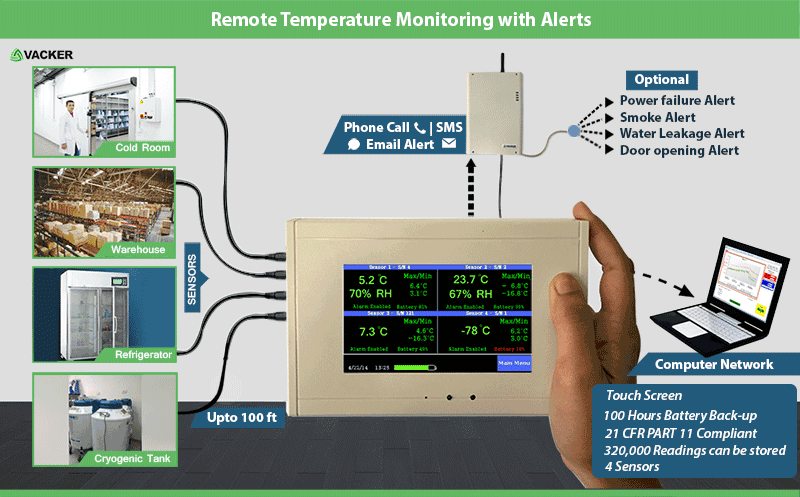

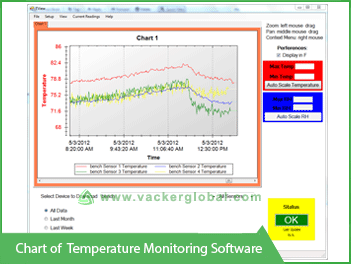

Numerous sensors namely temperature sensors, pressure sensors, humidity sensors, etc., form the fundamental principle of all such systems. All these sensors constantly accumulate data in scheduled intervals which is commonly termed as a sampling interval. Such sampling intervals may vary from hours to micro seconds depending upon the sensitivity of the parameter that is being monitored. All the data that is collected by the sensors are transferred to a central base station. Various modes can be used in transferring the data which is explained briefly in the following article. The data collected by the sensors is transferred via internet by the central base station and the data is simultaneously analyzed for any possible alerts. Alerts in the form of SMS, email or voice mail is generated in case the parameters surpass the alert levels preset.

We have every answer for refrigerator and freezer’s monitoring:

Vacker Saudi Arabia or KSA delivers an entire solution for monitoring of refrigerators and freezers in regions or areas such as Dammam, Riyadh, Al Khobar, Jeddah, etc. Our salient features are as under:

- Assimilation of temperature data logger and humidity data logger that has the capacity of recording months of data.

- Sensors that can fit into any portion of the refrigerator and can be extended

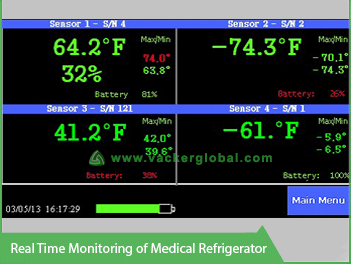

- One remote monitoring system can accommodate up to four refrigerators/freezers.

- Availability of a local screen on the refrigerator for the reading of current temperature and humidity.

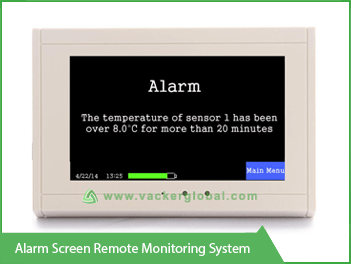

- Alerts in the form of SMS, email or phone call in case the refrigerator’s temperature or humidity crosses defined limits.

- Separate provision of monitoring door opening of refrigerators.

- Both monitoring system and the local area network can be used to record data.

- Variety in models that can function on radio frequency, Wi-Fi or Ethernet System.

- Fully compliant with the part 11 of 21 CFR US standards.

- Provision for complimentary software for remote refrigerator monitoring.

- In order to secure data loss during power failure, 100 hours of battery backup.

Nominal Specifications:

Short technical specification of remote refrigerator monitoring system and software provided by Vacker Saudi Arabia or KSA are as follows:

- Data log capacity of 80,000 readings.

- A single device can support up to 4 temperature sensors/temperature and humidity sensors.

- Variety in thermocouples (temperature range from -200°C to 1350°C).

- Alert Types: alerts for low temperature, high temperature and timer for each alert can be delayed too.

- Screen types: LCD touch Screen, size 6.35 cm x 11.43 cm.

- Alerts: SMS, email and phone call via external dialer.

- Dimension of the monitor (cm): 22 x 12.7 x 3.5

- Sensor types: Wireless and wired. Wireless sensors function on 433 MHz radio frequency.

- Sample interval: that can be set from 1 minute to 24 hours.

- PC Software: Complimentary (free of cost).

- Local network software (with email alerts): one time charge (Optional)

- Weight of monitoring device (without sensors): 510 gms

Kinds of real time remote temperature monitoring systems:

On the basis of device’s technology, Real Time Monitoring Systems can be classified as under:

- Based on Ethernet:

CAT6 cables and connectors are used to connect the sensors to the Ethernet system, just the way computers and printers are connected. But the availability of Ethernet ports near each sensor is a must. Electric plug or POE (Power over Ethernet) can be used to power them. A separate base station is not available however any computer in the network can be used a base station.

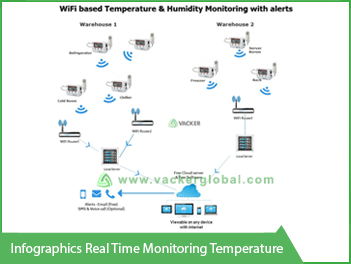

- Based on Wi-Fi Communication:

No Ethernet cable is required in this type. The sensor and the central station communicate through Wi-Fi routers, which are used to connect to other computers. Since Wi-Fi communication is power dependent therefore for non-stop transmission of data, sensors powered with an AC Supply are required. Devices that collect data and simultaneously store them but, transmit them only once or twice a day are also available. Systems like those can function on their own battery and that too for a long period of time since they are connected to Wi-Fi once or twice a day.

For this instance, a network computer is used as a base station instead of having a specifically different base station for it. However, the range and strength of the designated Wi-Fi router defines the entire communication reliability.

- Based on radio frequency:

Real time monitoring systems of such type function on the basis of radio frequency. The devices based on such modalities are preferred because of its high range of working realm. But prior to buying such devices it is suggested that the legality of the permit, provided by the local authority, which is a must, should be confirmed. A continuous communication of the base station (receiver) and the sensor (transmitter) takes place despite being distant from each other.

In such modalities, the sensor can work for a very long time on battery backup without an immediate power supply.

- Based on Zigbee Protocol:

As we all know that ZigBee is a latest wireless technology developed as an open global standard for addressing unique needs of economical, low-power wireless and has the range of up to a km aerial for such systems. Majority of the countries have already a predefined frequency range for the operation of Zigbee. Similarly to systems based on radio frequency, Zigbee also operates for a very long time on battery backup without an immediate power supply.

- Based on IP sensors:

Of all the monitoring systems, these are considered to be the most economical. The functionality of such models is very easy; to make them work you simply need to connect them to the Ethernet. Because it works on POE (Power over Ethernet) and it does not require power supply. Central software is designated for the server in the Ethernet System and each sensor is configured to the same software.

Assessment of various technologies in real time monitoring systems

| Parameters | Ethernet based | Wi-Fi based | RF based | Zigbee based | IP Sensors based |

|---|---|---|---|---|---|

| Operating frequency | Computer Networks | 802.11a/b/g/n/n-draft | Different for each country | 802.15.4 | Computer Network |

| Mobility of sensors | Depends on the length of wire | Within range of WiFi router (20-30 Meter) | Within range of Rf (300-400 Meter) | Within range of Zigbee signals (700-100 Meter) | Depends on the length of wire |

| Power supply | Compulsory | Compulsory | Not necessary | Not necessary | Not necessary(in majority) |

| Battery backup | Provided | Provided | Provided | Provided | Not provided generally |

| Battery Life | 2 weeks | 2 weeks | 2 Weeks - 1 Year | 2 Months - 1 Year | Not Applicable |

| Most fit for | Multiple rooms, server room | Refrigerators, rooms, server room | Open Warehouses | Open Warehouses | Multiple Rooms |

How do we choose among various real time monitoring systems?

Before making a choice among the various real time monitoring systems, following things should be considered:

- The nominal parameters that need to be monitored for your asset. The list of parameters may differ depending upon the asset you possess.

- The type of real time parameter monitoring systems. Depending upon the flexibility for the relocation of small assets, Wi-Fi, Radio Frequency or Zigbee based system can be chosen. Similar is the case for the moving racks.

- For more economical results, apply Ethernet based or IP based systems if you possess only fixed assets.

- The Specific type of alerts that you wish to notify to yourself (for example, SMS, Email, phone calls, etc.)

- In case of power cut or communication error, the sensors should not stop working. The sensor should possess a memory store of its own so that the data is transmitted to the base station once the power restores.

- For those to whom alert is considered vital, the alert system should have an uninterrupted functionality even in situations when there is power cut, server down or communication error. Having an independent battery backup for such systems is considered fundamental.

- The accuracy of the parameters for those who seek precision.

- Display of current reading of each sensor screen. Depending upon your requirement such display screens can be used in your assets. However the readings can be displayed in the designated base station as per your requirement.

- The memory capacity of the sensors should be considered too. For places where there is frequent power cut or server failure, sensors with higher memory is preferred.

- For those who abide by the US Standards, devices that compliant are with and should have been tested with 21 CFR Part 11 should be chosen.

- Is there or not any annual management fee associated with the system?

- Simplicity in the annual calibration of the sensors.

- Depending upon the source of power in the area it is necessary to calculate the power supply provision for the sensors. And thus the system can be chosen.

- The nature of the battery and its battery backup should be considered too.

- A prompt alert type in case of battery level drops below critical level if the sensors lack power supply.

- Browser-based systems are also considered good because it can be used via web browsers and the mobility of the one using it can be facilitated.

- For those who are technically inclined, a mobile application can be installed hence you need to check whether or not the system comes with such applications.

An evaluation sheet can be used in order to compare various manufacturers prior to finalizing a remote monitoring system.

Do you wish to record data directly from your delivery vehicle?

Life will be so easy if you could record data immediately from your delivery vehicle. Most customers seek this faculty as they own such multiple vehicles for the delivery of goods especially in the case of warehouses. Real time monitoring systems based on GPRS can also be used in such cases. But this is comparatively expensive.

Other way round, the vehicle can store the data while it is away from the realm of the warehouse and can start transmitting the data via various forms once it enters the range of the warehouse. The delivery vehicles can have sensors so that they can remit the data to the base station immediately after coming to the range of the base station.

For more details you can watch these videos in the following links:

Installation videos:

- Temperature and Humidity recording and Alert System Data Logger.

- Configure IP Address of Temperature and Humidity monitoring System Data Logger

- Calibrate the Sensors of Temperature and Humidity Monitoring System Data Logger