In today’s competitive industrial landscape, efficient material handling is a paramount requirement. Forklifts, pivotal for the movement of goods and materials within warehouses and distribution centers, hold a vital role. However, with operations becoming more intricate and safety standards growing increasingly stringent, the demand for advanced forklift monitoring systems has surged.

These monitoring systems are instrumental in optimizing forklift operations, bolstering productivity, and ensuring the safety of both forklift operators and those in their vicinity. A synergy of hardware and software components enables the real-time collection, analysis, and visualization of data. The introduction of forklift monitoring systems has brought about a transformation in industrial processes, resulting in heightened efficiency and safety standards. The ability to track and analyze data in real time has facilitated precise inventory management and streamlined logistics, consequently elevating productivity and minimizing downtime. Moreover, a decrease in accidents and injuries has been witnessed, thanks to enhanced safety regulations and insights into driver behavior and vehicle performance.

The integration of smart technology ensures proactive maintenance, reducing the likelihood of unforeseen breakdowns. In essence, forklift monitoring empowers companies to optimize resources, streamline operations, and foster a secure environment, ushering in an era of risk-free and seamless material handling. Let’s delve further into the key components, features, and advantages of forklift monitoring systems.

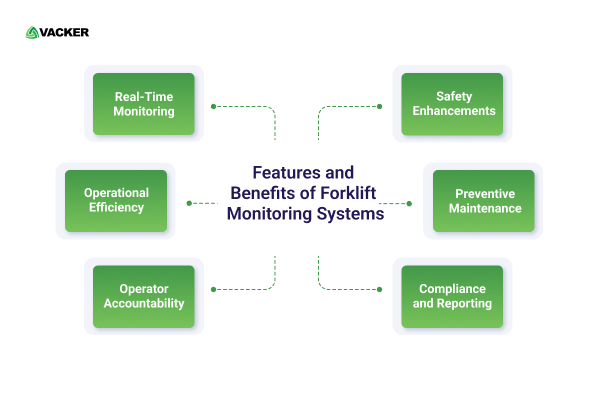

Advantages of Forklift Monitoring Systems

- Informed Decision Making – Forklift monitoring systems provide detailed analytics, empowering managers to make informed decisions based on data. This leads to continuous process improvements and a competitive edge.

- Cost Reduction – These systems incorporate predictive maintenance features that prevent unplanned breakdowns and equipment failures, ultimately reducing repair costs and downtime. Additionally, optimizing routes and enhancing operator efficiency can lead to reduced fuel or power consumption, further cutting operational costs.

- Enhanced Safety – Safety is paramount when handling materials. Forklift monitoring systems play a vital role in improving safety by delivering immediate notifications, encouraging cautious driving behavior, and assisting operators in avoiding accidents. This significantly reduces the risk of workplace incidents.

- Compliance and Accountability – Implementing forklift monitoring systems ensures compliance with safety and operational regulations. Furthermore, the data collected can be used to assess operator performance and promote accountability within the workforce.

- Increased Productivity – Utilizing this technology enables the identification of inefficiencies and bottlenecks through the analysis of forklift movements and operator performance. Armed with this information, managers can implement measures to optimize routes, streamline processes, and ultimately enhance overall productivity.

Components and Features of Forklift Monitoring Systems

- Operator Performance Evaluation – Forklift monitoring systems incorporate sensors to assess the performance of forklift operators. Metrics such as speed, acceleration, and deceleration are analyzed to gauge operator competence and adherence to safety protocols. This data serves as a foundation for offering recommendations and implementing training programs to enhance operator skills and mitigate accident risks.

- Maintenance and Diagnostic Insights – Regular servicing is vital for maintaining forklift durability and efficiency. Forklift monitoring systems provide valuable insights into the condition of critical components, including engine performance and tire pressure. Predictive maintenance algorithms identify potential failures in advance, facilitating proactive repairs and minimizing downtime.

- Collision Avoidance Technology – Modern monitoring systems employ collision avoidance technologies, such as proximity sensors and cameras, to swiftly detect potential collisions and alert operators. Some systems even feature autonomous braking capabilities to prevent accidents.

- Data Analytics and Reporting – These systems accumulate substantial amounts of data, which can be analyzed to identify trends, patterns, and areas for improvement. Managers have access to comprehensive dashboards and reports that cover forklift operations, operator performance, and safety incidents. These insights empower decision-makers to optimize material handling by making informed choices.

- Battery Management – Electric forklifts are favored for their cost-effectiveness and environmental benefits. Forklift monitoring systems include battery management components to oversee battery charge levels, monitor usage patterns, and assess battery health. This information allows for the enhancement of battery charging and replacement schedules, ensuring uninterrupted operations and prolonged battery life.

- Vehicle Location Tracking – These systems utilize GPS and RFID tracking to pinpoint the exact location of forklifts within a facility. Real-time tracking allows managers to monitor forklift locations, and plan and adjust routes for improved efficiency.

Areas of Implementation for RTLS Technology

Real-Time Location System (RTLS) technology has found applications in various domains, offering precise tracking and monitoring capabilities. Here, we delve into the diverse implementation areas where RTLS technology is making a significant impact –

Employee Tracking

Employee Tracking RTLS utilizes cutting-edge technology to monitor and manage the workforce efficiently. By equipping employees with advanced sensors and tags in the form of ID badges or belt clips, this system provides real-time data on their locations and movements within the workplace. The seamless integration of ultra-wideband (UWB) RTLS technology with wireless rechargeable employee trackers creates an “indoor tracking system,” optimizing workflows, enhancing safety, and boosting productivity. With Employee Tracking RTLS, businesses can make data-driven decisions, streamline operations, and ensure compliance with safety protocols, ultimately creating a safer and more efficient work environment.

Emergency Mustering

In times of emergencies or evacuations, Emergency Mustering RTLS technology plays a vital role in enhancing safety. By using electronic ID badges with BLE Beacon technology, this system accurately tracks individuals’ real-time locations, facilitating swift and efficient mustering at designated assembly points. The badges emit distinct signals, allowing tablets and smartphones to read them from a considerable distance. This automated roll-call system integrates with time and attendance systems, automatically updating the attendance list. Operating on a cloud server with GSM communication, Emergency Mustering RTLS remains functional even when network and power connectivity fail, ensuring the safety of all personnel.

Infant Security

Infant Security Tracking and newborn Baby Protection is a paramount concern in healthcare settings. Utilizing advanced technology like RFID bracelets and CCTV monitoring ensures constant vigilance. Real-time tracking of newborns prevents unauthorized movements, reducing the risk of abductions. Motion sensors provide continuous health monitoring, and inactivity warnings alert hospital workers when a baby stops moving for an extended period. Geo-fenced regions can only be entered by authorized personnel, generating alarms if unauthorized individuals attempt to depart with an infant. These measures prioritize infant safety, allowing families to cherish precious moments without worry.

Patient Flow and Safety

Patient Flow & Safety RTLS optimizes healthcare processes, ensuring efficient patient movement and safety. Using technologies such as RFID, Wi-Fi, and GPS, this system tracks and monitors patient movements, reducing wait times and enhancing care coordination. RFID patient tags facilitate tracking, and recording when patients enter and exit rooms, visit different hospital areas, and undergo diagnostic and testing procedures. This technology empowers healthcare institutions to provide better patient experiences, increase operational efficiency, and prioritize patient well-being, ultimately leading to improved healthcare outcomes.

Pandemic Safety

In response to pandemics, Pandemic Safety RTLS technology enhances safety across various settings. It tracks the real-time locations of individuals and assets, enabling efficient contact tracing and social distancing monitoring. By equipping staff members with rechargeable badges containing UWB RTLS technology, this system establishes an “indoor tracking system” to accurately track employees and visitors. Personnel can be alerted of potential exposure through wearable devices or smartphone apps, facilitating quick isolation and containment measures. Pandemic Safety RTLS empowers organizations and communities to navigate pandemic challenges effectively, fostering a safer environment for all.

Lone Worker Safety

Lone Worker Safety RTLS technology is designed to ensure the safety of remote and isolated workers. By equipping staff members with rechargeable badges containing panic buttons and UWB RTLS technology, this system enables real-time monitoring of employees’ locations. This “indoor tracking system” enhances safety by sending notifications when lone workers reach distant locations, preventing accidents, and enabling prompt responses during emergencies. Lone Worker Safety RTLS empowers organizations to prioritize employee safety and preparedness.

Senior Living Safety

In senior living facilities, Indoor Tracking RTLS technology revolutionizes elderly care by providing precise location insights. Caregivers can monitor residents’ movements in real time, enhancing their safety and well-being. This RTLS tracking device is particularly beneficial for individuals with movement-related conditions like Parkinson’s or dementia. It sends automated alarms when a resident exits a predefined area or remains motionless for an extended period, improving response times and overall care quality. This unobtrusive solution promotes independence for seniors while providing peace of mind to families and caregivers.

Optimizing Industrial Operations – A Comprehensive Guide to Asset Implementation

Asset management and tracking systems have become indispensable tools in modern industrial settings. Whether it’s ensuring safety, enhancing efficiency, or preventing losses, these systems play a pivotal role. Let us explore various aspects of asset implementation:

Forklift Collision Warning

The Forklift Collision Warning System is a vital component of industrial safety. It utilizes sensors and alarms to alert forklift operators about potential collisions, whether with obstacles or pedestrians. By integrating battery-operated active RFID tags employing ultra-wideband (UWB) active RTLS technology, an invisible “indoor GPS system” is created, precisely tracking each forklift’s location. The data is processed using techniques like time difference of arrival, time of flight, and trilateration, resulting in real-time location information accessible through RTLS application software.

Forklift Tracking

Efficient warehouse management relies on real-time location monitoring, which is where Forklift Tracking comes into play. It combines GPS and RFID technologies to provide accurate information on forklift movements. The use of battery-operated active RFID tags and UWB RTLS technology, coupled with an RTLS mesh network, ensures pinpoint accuracy in tracking each forklift. Algorithms convert tag signals into precise location data, reported comprehensibly through RTLS application software.

Yard Management

Yard Management is a critical logistics process, optimizing goods movement and storage in facilities or distribution centers. It minimizes congestion and idle time, enhancing operational efficiency. This system employs rechargeable tags, and active RFID technology with UWB, IP67 anchors, gateways, and mesh positioning networks for precise location tracking. Yard management software processes location data in real time, enabling timely decisions, better coordination, and increased productivity across the yard, dock, and transportation operations.

EMS Inventory Tracking

EMS Inventory Tracking is paramount for monitoring medical equipment stock, preventing theft, and shrinkage, and ensuring timely response. The system employs a Vehicle Control Unit (VCU) linked to the GSM network, along with active RFID tags on each medical item. These tags transmit signals picked up by the VCU, continuously tracking equipment location and transmitting data to the EMS station. The system alerts staff if a tag goes out of range or stops transmitting, enabling real-time monitoring of item usage and possession, making it ideal for ambulance services, hospitals, and fire departments.

Process Tracking

Process Tracking involves monitoring and documenting workflows comprehensively. Battery-operated active RFID trackers, leveraging UHF RFID and UWB RTLS technologies, offer an “indoor tracking system” with exceptional precision. Proprietary methods convert signals from process-tracking RTLS tags into position data, which is then transmitted to process management software. This data is analyzed, displayed, and subjected to customized business rules, facilitating maintenance scheduling and process improvement.

Asset Tracking

Asset Tracking through Real-Time Location Systems (RTLS) empowers businesses to monitor and locate their assets accurately. It combines sensors, beacons, and wireless communication to offer real-time location, movement, and status information. Battery-operated active asset trackers, incorporating RFID and UWB RTLS technology, provide unparalleled precision in asset tracking. The RTLS mesh network further enhances tracking accuracy. Signals from RTLS asset tags are translated into location data, processed, and presented clearly via asset management software.

Revolutionizing Industries with Real-Time Location Systems (RTLS)

Manufacturing: Creating a Safer Working Environment

In the manufacturing sector, RTLS is making waves by providing real-time visibility into employee whereabouts and statuses. By accurately tracking employees, assets, and vehicle movements, RTLS enhances workplace safety and reduces accidents. It achieves this by configuring automatic notifications, establishing geofences, and even limiting forklift speeds. In case of an evacuation, an automated mustering roll call expedites headcounts. Integrating RTLS into Industry 4.0 initiatives empowers businesses with actionable insights, fostering a smarter, more connected, and agile manufacturing ecosystem.

Supply Chain & Warehousing: Efficiency and Safety First

For supply chain, logistics, and warehousing, RTLS optimizes operations by offering precise, continuous location data for assets and inventory. Utilizing technologies like RFID, Bluetooth, or GPS, RTLS minimizes delays, enhances efficiency, and maintains a secure working environment. With real-time location data made possible by UWB RTLS technology, personnel oversight becomes more manageable, potential dangers are spotted, and emergency responses are improved. The autonomous forklift speed control and operator warning system keep accidents at bay. Geofences around accident-prone areas ensure adherence to safety regulations, ultimately resulting in seamless operations, faster response times, and heightened customer satisfaction.

Oil, Gas & Mining: Enhancing Safety and Efficiency

In the oil, gas, and mining industries, RTLS offers precise, instant asset tracking using technologies like GPS, RFID, and wireless networks. This technology enhances safety, operational efficiency, and cost-effectiveness. With real-time tracking of people and assets, mining and oil and gas sectors benefit from enhanced safety features, including emergency headcounts, last known whereabouts, and fall detection tools. RTLS empowers these industries with informed decision-making capabilities, driving improvements in overall performance and safety.

Healthcare: Elevating Patient Care

In healthcare, RTLS tracks and monitors the precise location of medical equipment, patients, and staff within healthcare facilities. This system improves workflow efficiency, patient safety, and asset utilization by leveraging RFID, Wi-Fi, or Bluetooth technologies. Healthcare RTLS systems protect property and offer ongoing patient status monitoring to prevent falls and enhance security. These systems empower healthcare providers to deliver better patient outcomes while streamlining internal logistics and increasing operational profitability.

Aviation: Streamlining Operations

For aviation, RTLS accurately tracks aircraft, personnel, and assets in real time. This technology optimizes airport logistics, reduces delays, and enhances security. With advanced sensors and wireless communication, RTLS provides accurate location data, enabling better aircraft monitoring, streamlined ground operations, and improved emergency response. It brings real-time visibility and data-driven decision-making to the aviation industry, ensuring a safer and more productive environment for all stakeholders.

Construction: Smarter Sites

In the construction sector, RTLS uses advanced technology like GPS, RFID, and sensors to track and manage equipment, materials, and workers in real time. This precise asset location tracking optimizes workflows, enhances safety, and improves resource utilization. Real-time monitoring ensures construction sites meet safety standards, and workforce analysis enhances staff utilization. Detailed usage and movement reports serve as valuable evidence in case of claims or accidents. RTLS transforms construction sites into intelligent, responsive environments, resulting in faster, safer, and more cost-effective project completions.

Automatic Speed Reduction System for Forklift Anticollision

In the realm of forklift safety, an innovative automatic speed reduction system takes center stage, ushering in a new era of collision prevention. This system operates seamlessly through a multi-tiered process encompassing detection, analysis, and responsive actions.

Advanced sensors and strategically positioned cameras work in harmony, collecting a wealth of data from the forklift’s surroundings. This comprehensive dataset undergoes scrutiny by AI algorithms, employing intricate models to decipher patterns, predict collision probabilities, and calculate the optimal speed reduction necessary to avert impending disasters. In the decision-making realm, an array of variables comes into play. The forklift’s velocity, its trajectory, the load it carries, and the presence of obstacles or pedestrians all factor into the equation. This holistic approach ensures that speed reductions occur with both precision and timeliness, safeguarding against disruptions while prioritizing safety above all else.

When the system detects a collision risk on the horizon, it promptly communicates with the forklift’s control unit. This seamless fusion of real-time data analysis and swift decision-making leads to an automatic adjustment of the forklift’s speed, aligning it with a safer and more appropriate pace. This proactive stance effectively minimizes collision risks and the subsequent damage to goods, infrastructure, and equipment.

Versatility is a hallmark of this system, making it adaptable to diverse operational environments, including warehouses, distribution hubs, and manufacturing facilities. It seamlessly blends safety with efficiency, exemplifying how technology can enhance workplace well-being. Ultimately, this synergy results in a safer and more productive work environment.

In the broader landscape, the integration of such safety mechanisms promises to transform forklift operations. Industries embracing these advancements can anticipate elevated safety standards, streamlined processes, and a notable boost in overall productivity.

In the ever-evolving logistics landscape, businesses are increasingly prioritizing safety and efficiency in material handling operations. To achieve this, forklift monitoring systems have emerged as a game-changing solution. These systems leverage advanced technology to track forklifts, scrutinize operator performance, and analyze critical data. The result? Elevated productivity, cost reduction, and an unwavering commitment to safety. As various sectors continue to advance, the integration of forklift monitoring systems becomes an imperative step for businesses seeking success in the contemporary logistics arena. For further information, don’t hesitate to get in touch with us. In KSA, we supply these forklift anti-collision systems in Jeddah, Dammam, Tabuk, Jubai, Riyadh, Jizan, and more areas.

In the Middle East, we supply these forklift anti-collision systems in the Kingdom of Saudi Arabia, United Arab Emirates, Oman, Qatar, Bahrain, Iraq, Lebanon, Egypt, Jordan, Libya, Tunisia, etc.

In Africa, we serve countries including Kenya, Algeria, Tanzania, Djibouti, Chad, Ghana, Rwanda, Uganda, Nigeria, Ethiopia, Morocco, Angola, South Africa, etc.

Disclaimer: This page is translated using Google Translation tool. Please contact us for any kind of confusion or clarification.